Who We Are

Modelleria Yacht Design is a cutting-edge company specializing in the large-scale production of models and fiberglass mold creation for luxury yacht manufacturing.

By adopting innovative technologies and relying on a highly skilled team, we offer tailor-made solutions for yacht manufacturers, ensuring precision and attention to detail throughout every stage of the production process.

Our mission

We are committed to supporting our clients in the development of high-quality nautical products, providing a complete service from design to final production. Our vision focuses on optimizing production time and ensuring the highest quality results.

Our Workflow

Designed to ensure complete control over every phase, from receiving initial specifications to delivering the finished product. Every step is managed in-house, with no subcontracting, to guarantee maximum consistency and precision. Below is the workflow we follow with each client:

Receiving the Final Product Specifications

The process begins with the reception of the final product’s mathematical models provided by the client. These data serve as the foundation for the design phase.

Design and Milling Path Programming

Our technical office defines the project phases, first for the model and then for the mold, including details for the necessary finishing touches. Using advanced software (CAM Tebis, Rhino3D, and Aspire), we optimize milling paths to ensure an efficient and error-free production process.

Material Preparation

Simultaneously, the metal carpentry department designs and manufactures the support frame, first for the model and then for the mold. At the same time, polystyrene is cut using our CNC hot-wire system and assembled to create the masses ready for milling.

Model Milling

The polystyrene masses are then milled under thickness using the CMS 5-axis CNC milling machine (with a working range of up to 30 meters), followed by the application of epoxy paste and a subsequent milling process to achieve nominal geometry.

Assembly and Lamination

Once milling is complete, the model is stiffened and coated. The next step is the mold lamination phase.

Technologies and Production Capabilities

Modelleria Yacht Design has a 6,000-square-meter facility divided into specialized departments that work in synergy to ensure maximum quality and efficiency. Our main operational departments include:

• Metal carpentry

• CNC milling

• Technical design office

Our team of expert designers and engineers assists clients in developing customized solutions, ensuring that each project phase meets the required technical and aesthetic specifications.

Collaboration with Yacht Design

To provide a comprehensive and highly specialized service, Modelleria Yacht Design works closely with Yacht Design, a division specializing in fiberglass manufacturing.

The synergy between the two companies enables us to manage the entire process, from the initial design to the final realization of the product, complete with high-quality professional painting.

Why choose Modelleria Yacht Design?

Integrated and seamless process

We manage every phase internally, ensuring consistency and quality at every step.

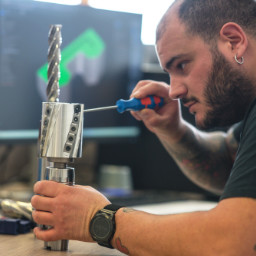

Cutting-edge technologies

We use advanced machinery and software to optimize the production process and ensure maximum precision.

Experience and specialization

Our highly qualified team is able to satisfy the most complex needs of the nautical sector.

Effective collaboration

Close cooperation with Yacht Design allows us to offer complete project management.